Precision Metal Stamping

Our state of the art Manufacturing Equipment allows us to produce quality precision metal stampings of .003″ – .100″ thick materials from Progressive Dies. All tooling is built in-house and is approved by our Customers prior to running any production. The Progressive Dies are run on our Komatsu presses from 45 – 80 Ton. On some presses we utilize quick die change methodology. Unless Otherwise agreed upon, we check all CTF dimensions, during our in-process inspection.

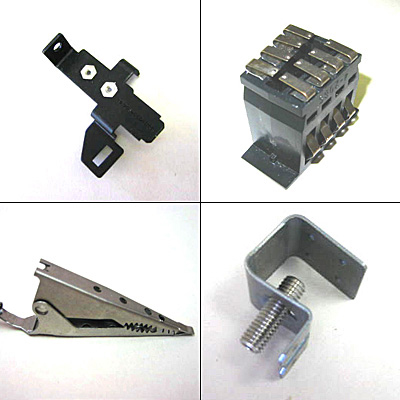

Brackets

We manufacture brackets in all types of configurations. We can make your brackets from Stainless Steel, Aluminum, Copper, Mild Steel, and in any metal thickness from .005″ to .125″ thick. We can also design stiffening ribs into the form tooling for added strength.We also install hardware as required and offer many different finishing processes for our valued customers.

Contacts

We manufacture contacts for many of our customers. These parts are usually very precise and require great attention to detail. We can make your contacts from EG Steel, Stainless Steel, DR-9, Beryllium Copper,Phosphor Bronze, and in any metal thickness from .003″ -.125″ thick. We perform our own in-house age hardening as required and can provide many different plating and finishing options.

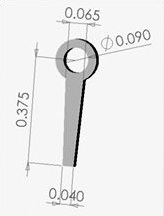

PC Board Test Points

We manufacture PCB test points that can be placed in ground locations on PC Boards. We offer these points in 1000 piece quantities. The points are made from tin plated brass and are stamped to these dimensions.

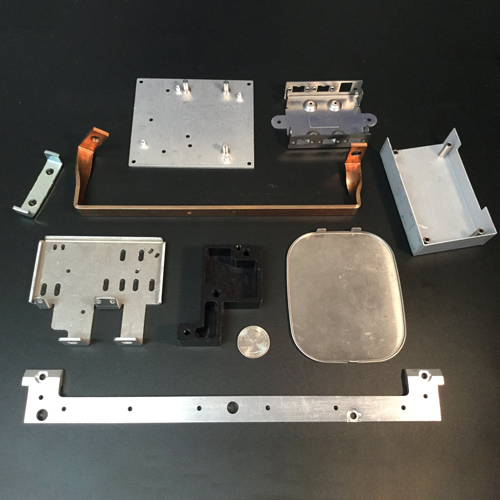

Precision Thin Sheet Metal

Our ability to produce both lazercut precision thin sheet metal parts from .005”-.060” and form these complex parts on our precision servo press brake, is second to none!

Shielding

We manufacture shielding typically from .003″ -.020″ thick materials. Typical materials used are Stainless, DR-9, Beryllium Copper or Tin Plated CRS. We perform our own in-house age hardening as required.